In optical imagers, there are three main types of illumination: surface light illumination, contour light illumination, and coaxial light illumination.

These three lighting methods have been widely used at present, according to the measured products and measured data, select the appropriate lighting method. For example, you can use the bottom light to measure the outline of the outside, and measure the size of the product surface. The bottom light can not be measured. The surface light can be used to measure the deeper holes. The surface light is not clear. Coaxial light can be used for measuring products such as lines in the glass of mobile phones. Choosing the right light source can measure the required data more efficiently and accurately.

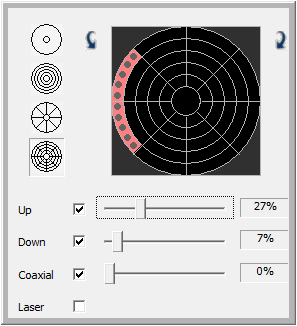

The current development trend of surface light is to use ring-shaped surface light sources to provide multi-directional and multi-incidence surface illumination. The ring area provided by different light sources is different. The image measuring instrument of Longtian Instrument generally provides LED surface light illumination of 4 rings and 8 areas. Each unit can independently control the switch and brightness, and the installation angle of each ring is also different. Can provide illumination at different angles of incidence.

Contour light illumination is very different from other illumination methods because the image sensor receives not the reflected light but the incident light.

Contour light illumination can produce strong contrast. With contour light illumination, the surface features of the workpiece are lost, but the surface contour information of the workpiece can be clearly obtained. The outline light source can distinguish the light-transmitting and opaque parts, the light-transmitting part is white, and the opaque part is black, so a black-and-white contrasting image can be obtained.

The coaxial light illumination of the optical coordinate measuring instrument is usually used to detect the invisible object data in the workpiece. The coaxial light source is very effective for the illumination of the workpiece surface with mirror characteristics, and can also be used for the illumination of deep hole workpieces.